Spot & Roll Seam Welding

Yaskawa Slovenia Študije primerov Aplikacije Spot & Roll Seam Welding

Pregled

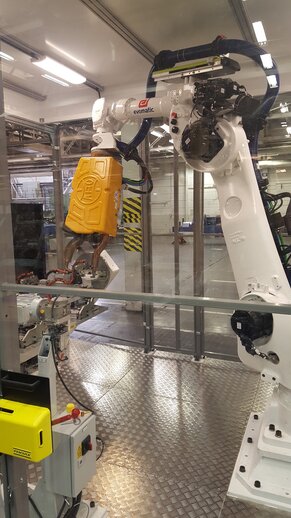

Spot Welding with Motoman Robots

Robotic Spot Welding Applications are most common in Automotive OEM and Tier1 Body Shops, automatically assembling car bodies and their sub-assemblies. We have collaborated with automotive OEMs to create innovative robots to improve body shop productivity, and to comply with their body shop standards, leading to an installed base of ten-thousands of Motoman Robots throughout the world. We are offering the full bandwidth of robots models and technology required here - payloads, reaches, integrated and external spot harnesses / dress packs and servo-controlled spot guns.

Not only large Automotive OEMs, but also European Tier1s, supplying car body subassembly plants, are very open to innovative products and lean approaches in spot welding.

There is a large field of spot welding applications in General Industry (outside of Automotive). YASKAWA Motoman is the right partner to realize spot welding solutions here.

Motoman Spot Welding Robots

As a company with international footprint, we successfully transferred the Japanese Automotive Spot Welding philosophy into the European Tier1s, as an alternative to the European trend to larger payload robots and heavy spot guns. The Japanese Production line philosophy is preferring smarter, smaller robots and lighter spot guns and condense the number of spots per cycle, and to achieve savings in terms of cost, floor space and environmental CO2 Footprint. So, in addition to the classical European portfolio of Spot Welding robots (mainly specified by the Automotive Body Shops), we introduced a series of robots designed for higher robot density.

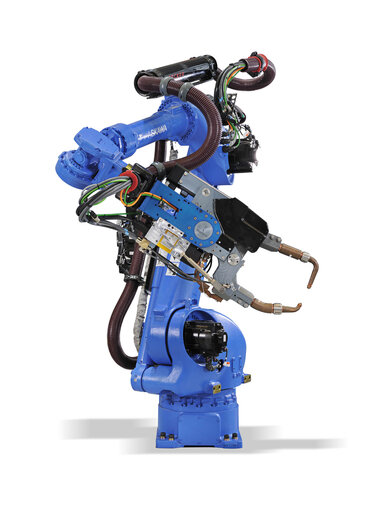

The SP80, SP100 and SP165 are slim-profile robots that can be positioned closer to the workpiece and allow the product to be produced with fewer re-spot stations. SP165, SP210, SP215, SP250 and SP280 are classical spot welding robots with small footprint, high speed and positioning accuracy and - if required - internal cabling for 7th axis servo guns.

Spot Welding Solution Packages

And we combined this lean robotic idea with our positioners, spot gun and integration expertise, offering perfect spot welding technology bundles.

Turnkey Spot Welding Workcells

We revolutionized the robotic arc welding industry with a diverse offering of standardized pre-engineered workcells called ArcWorlds. We do also offer standard turnkey spot welding cells, which combine a variety of part holding positioners, process equipment and safeguarding. These workcell configurations have been utilized in a wide range of industries, including automotive Tier suppliers, agriculture/construction equipment manufacturers and medical equipment manufacturers.

Welding Guns, Controllers and Weld Timers

Basically, we work with the leading spot welding gun and weld timer manufacturers and integrate them into our core controls and software, resulting in a more flexible, high-performance system. This ensures the compatibility to plant and technology standards, specifically with larger Automotive and Tier1-Customers.

Our robot controllers interface with all common gun design and control methods, including:

- Pneumatic guns with additional pneumatic arm compensation

- Servo-Pneumatic guns compensated by the robot arms (only Automotive).

- Servo-Electric guns with separate gun controller (only Automotive).

- Servo-Electric guns controlled as a 7th axis, compensated by the robot arm (the most common solution both Automotive and General Industry)

By using mid-frequency inverters for DC welding, transformer sizes have been greatly reduced. We have also worked with gun manufacturers to utilize higher frequency inverter switching (1,800-2,000 Hz) to help reduce gun size and weight, resulting in a more efficient and smaller system. We are open to all Weld Timer suppliers, and support their signal exchange and weld parameter management softwares.

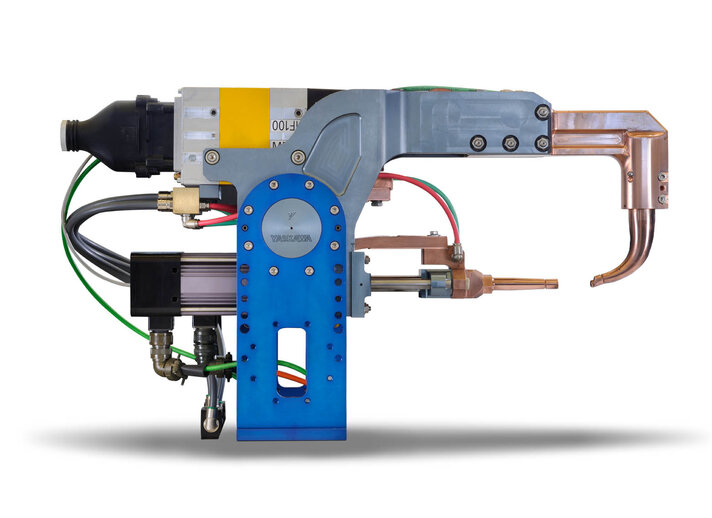

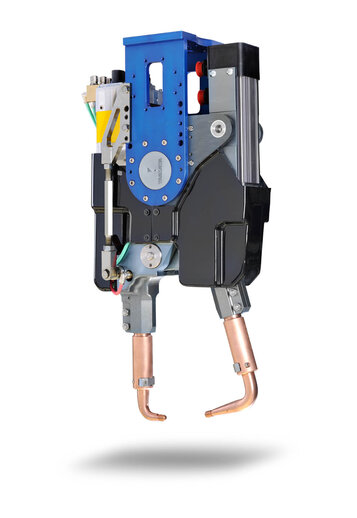

Yaskawa Compact & Lightweight Servo Guns

Yaskawa Europe designed our own portfolio of compact & lightweight spot weld C-Type and X-Type guns, perfectly fitting to the compact spot welding robots SP80, SP100 and SP165.

Servo Guns Software Options

A servo spot welding gun enables the robot to adjust electrode position based on motor torque feedback to provide the specified clamping force. Below are several benefits of servo guns:

- Minimizes electrode wear resulting in increased uptime

- Improves quality by providing consistent clamping force

- Improves Cycle time, as the gun can open/close in parallel to the robot's motion

- Eliminates “squeeze time” wait for an air-gun to close resulting in reduced cycle time

- Servo-controlled guns are more energy-efficient than pneumatic guns driven with compressed air, resulting in real cost savings

Our software provides easy calibration for X or C type guns and supports offsets for gun arm deflection and tip wear compensation. Stepped pressure files allow the gun pressure to be varied during the welding cycle or during a tip dress cycle.

The spot welding harness supports motor and encoder cables for Yaskawa Sigma-5 servo motors, which can be integrated with the gun manufacturers drives. Servo Drive Control kits are available for Yaskawa Motors, Obara lightweight motors, Tolomatic ServoWeld actuators and Exlar actuators.

Workpiece Positioners

We offer an extensive line of standard robotic positioners, all of them perfectly synchronized with the motion of robot and servo gun. One of the highlights is our RWV2 Turntable, with 1 or 2 robots sitting on top of a moving turntable - not beatable in terms of cycle time and installation space.

Tracks

With the TSL-1000, TSL-2000 and TSL-400 Series, Yaskawa offer a full portfolio of robot tracks, designed for Spot Welding and Handling Applications in Automotive Body Shop. All tracks are designing and manufactured in-house, ensuring highest expertise, quality, and attractive cost due to the short supply chain. All tracks are controlled by powerful Yaskawa Servo Motors and tuned to impressive motion speed while using high quality components.

Coordinated Motion and Multiple Robot Control

We were the first robot company to develop coordinated motion of multiple robots from one controller. Coordinated motion enables multiple robots to work within the same space without the risk of one robot interfering with another. This feature allows our robots to manipulate larger parts for multiple process robots or work closely together without collisions. Coordinated motion also extends to external servo axes in our positioners, simplifying complex operations.

Lap Spot Welding with Motoman Robots

Spot Welding is not always working with weld guns...

Stud Welding with Motoman Robots

Stud welding is a common application in Automotive Body Shops.

Ultrasonic Spot Welding Inspection with Motoman Robots

MotoSim Offline Simulation Engineering Tool for Spot Welding

Of course, our MotoSim Offline Planning Tool supports all kind of Spot Welding Applications, including Master/Slave-combinations.

Offline Simulation Software Support and RCS Module

YASKAWA is supporting the vcomplete ecosystem of Offline-Simulation Tools, providing kinematic CAD robot models and RCS Modules.